- The textile market situation of "Golden September and Silver October"

- In September, as the coolness of autumn begins, Xuhang New Materials'

- The critical period for the textile industry in 2025!

- Xuhang New Materials: Summer Automotive Interior non-woven fabric, Cooling down the driving and Riding Space

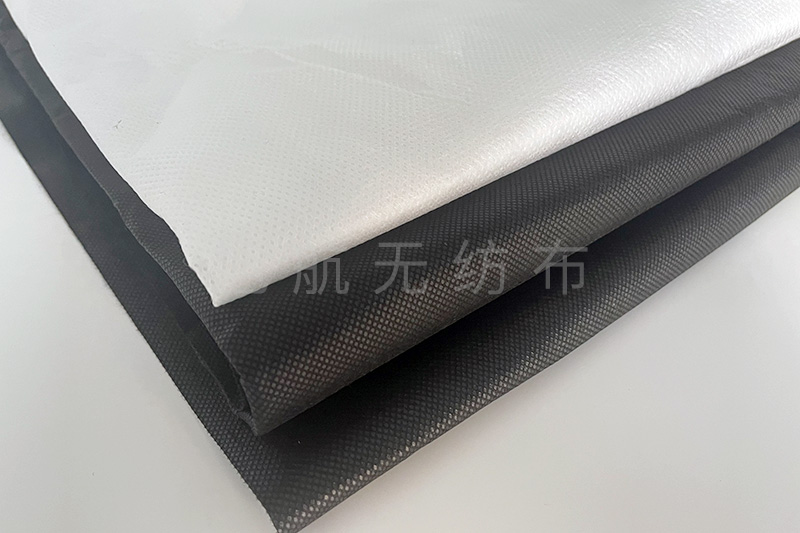

- Xuhang New Materials specializes in the production of non-woven fabrics for automotive interiors and is contributing to the automotive industry with its high-quality products!

- The textile industry achieved a stable start in the first quarter of 2025!

- Contact: Mr Li

- Tel: 0086-139 2680 4227

- Fax: 0086-0769-85080625

- Email: xh@xhnonwovens.com

- Add: No. 15, Baihao Industrial Street, Houjie Town, Dongguan City, Guangdong Province

(1) Overview of scale

The nonwoven industry can be divided into spunlace, spunbond, needle punched, thermal bonding, chemical bonding and other categories according to the production process. Among them, the subdivided spunlace nonwovens industry is one of the fastest growing areas in the nonwovens industry. According to data from the China Industrial Textile Industry Association, the actual domestic production of spunlace nonwovens increased from 232,000 tons to 698,000 tons from 2010 to 2019, with an average annual compound growth rate of 13.02%.

(2) Development history

The nonwoven fabric industry originated in Europe and the United States in the 1950s and was introduced to China for industrial production in the late 1970s. During the development process, nonwovens gradually evolved into spunbond, needle punched, spunlaced, chemical bonding, thermal bonding, airlaid, wet, meltblown and other processes. According to the statistics of the China Industrial Textile Industry Association, the production process of China's nonwoven fabric industry is mainly spunbonded. In 2019, the output of spunbonded nonwovens was 3.0943 million tons, accounting for 49.80% of the total output of nonwovens. Mainly used in sanitary materials and other fields; followed by acupuncture technology accounting for 23.03%, spunlace technology accounting for 11.23%, chemical bonding technology accounting for 6.43%, thermal bonding technology accounting for 5.33%, air-laid technology accounting for The ratio is 2.47%, the melt blown process accounts for 1.07%, and the wet process accounts for 0.64%.

(3) Features and advantages

Compared with traditional textiles, non-woven fabrics have the following three major advantages: 1. Non-woven fabrics have a wide range of raw fiber sources and strong adaptability. Most natural and non-natural chemical fibers can be used in the production of non-woven fabrics. 2. Non-woven fabrics have a unique engineering structure, and the production process is flexible and changeable. Through various subsequent finishing processes, textiles with various functional characteristics can be produced, including filtration, reinforcement, isolation, etc., so its application range is more extensive And it is expandable; Third, the production process of nonwovens is short, the number of labors is small, and the overall cost is low. It has unique advantages in more and more disposable consumption fields.

Based on the advantages of nonwovens production technology and product performance, the nonwovens industry has developed rapidly in my country. At present, China has become the world's largest nonwovens producer and consumer. According to the statistics of the China Industrial Textile Industry Association, my country has been continuously increasing investment in nonwovens fixed assets investment in recent years. In 2012, my country's nonwovens fixed asset investment was 14.66 billion yuan, and it has risen to 347.76 in 2017. 100 million yuan, with an average annual compound growth rate of 18.86%.

(4) Industry prospects

In terms of application fields, the current application of nonwovens is focused on the penetration of high-tech and the use of new materials. It is widely used in construction, automobiles, clothing, sanitary materials, aerospace, environmental protection and other industries, especially in the market for sanitary materials. The volume is gradually expanding, and the automotive textiles, footwear and artificial leather markets are also showing a new atmosphere. With its high added value and high efficiency competitive advantages, nonwovens have great potential in the industry.

(5) Competitive analysis

The differentiation of the development of enterprises in the industry has initially appeared, and a few outstanding enterprises have come to the fore. In recent years, with the development of the industry, some advantageous companies in the industry, including companies, have accelerated their development by relying on their own advantages in scale, capital, technology and operation, focusing on the mining of production processes, the expansion of product categories and the improvement of product quality. The promotion has enabled a small number of companies, including the company, to establish a good reputation and brand influence in the industry.

- In September, as the coolness of autumn begins, Xuhang New Materials'

- The textile market situation of "Golden September and Silver October"

- The critical period for the textile industry in 2025!

- Xuhang New Materials: Summer Automotive Interior non-woven fabric, Cooling down the drivin

- Xuhang New Materials specializes in the production of non-woven fabrics for automotive int

- The textile industry achieved a stable start in the first quarter of 2025!

- The non-woven fabric for automotive interiors has outstanding functional flame-retardant p

- The development prospects of the textile industry in 2025!

- There is light in the ordinary. Salute to the workers | Dongguan Xuhang New Materials Tech

- How should enterprises respond to the impact of repeated tariffs